which of the following is a type of machine safeguarding osha 10

Wrists are connected by cords and secured to a fixed anchor point which limit operators hands from reaching the point of operation at any time. A safety device may perform one of several functions.

Machine Guarding Best Practices Occupational Health Safety

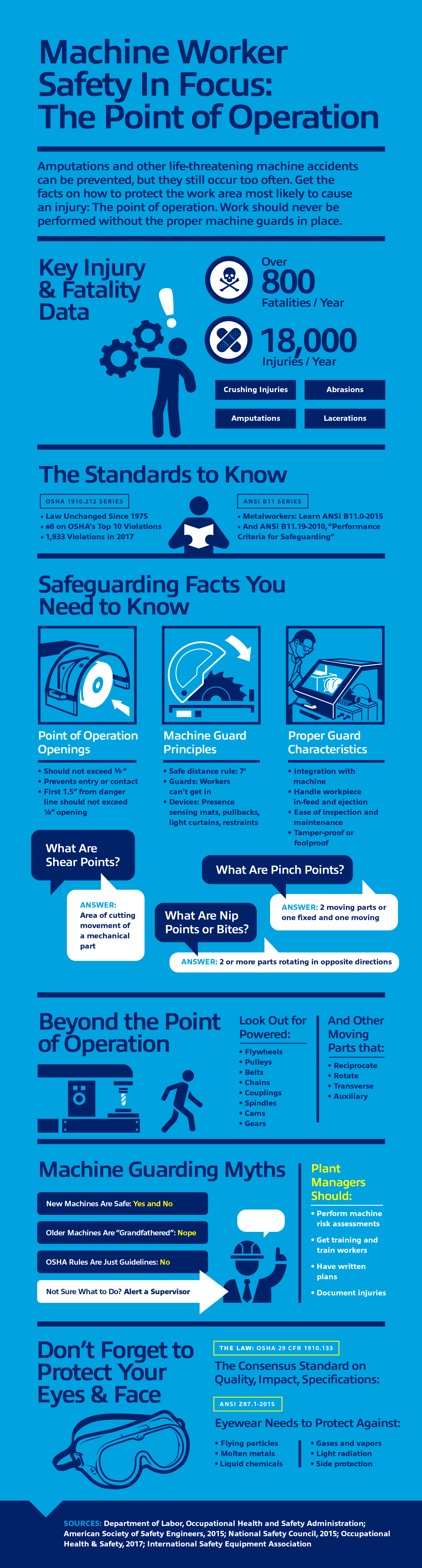

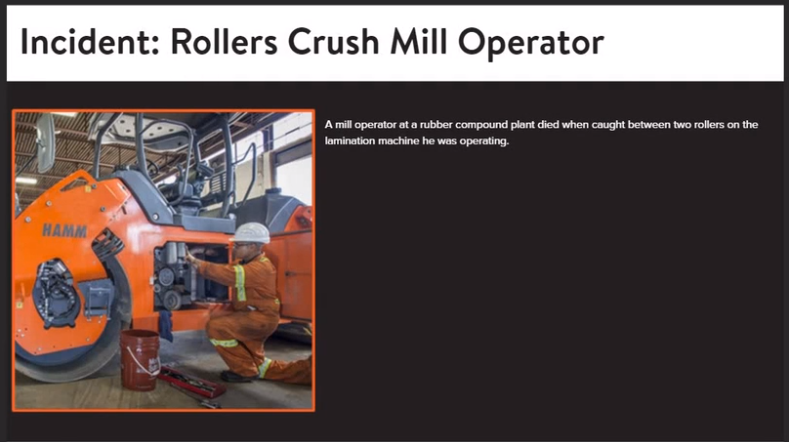

Crushed hands and arms severed fingers blindness -- the list of possible machinery-related injuries is as long as it is horrifying.

. A True b False. The Occupational Safety and Health Administrations OSHAs requirements for machine guarding are found in 29 Code of Federal. We can group machine safeguards under five general classifications.

These include moving belts arms. General Industry Machine Guarding v030117 21 Created by OTIEC Outreach Resources Workgroup Machinery That Requires Guarding Exposure of fan blades. Machine safeguarding helps protect workers from preventable injuries in all three areas.

Secondary methods of guarding machines. Any part of a machine which ___ while in operation can cause a hazard. Hazards of Moving Parts.

Stops the machine when a worker enters the danger area. There are several mechanical motions that pose risks to workers. OSHA states that mechanical hazards are most likely to occur in three major areas.

Good to operate. An employee trained on his you can take it off as long as you area are protected also you are. Any machine part function or process that may cause injury must be safeguarded.

The point of operation from where all the work is performed. Interlock into the machines control system to stop operation when the sensing field photoelectric radio frequency or electromagnetic is disturbed. Good machine safeguarding makes it very difficult for anyone to be exposed to the danger zone.

This course introduces the student to the basic concepts and principles for machine safeguarding as described by OSHA in 1910 Subpart O Machinery and machine guarding. Which of the following is a type of machine safeguarding. Power transmission apparatus which feeds energy to machines.

1 Assigns responsibilities to those affected and outlines evacuation routes. Correspondingly what are the most common types of machine guarding. Connecting the machine to an energy source Question 1.

This problem has been solved. Moving parts which are part of the machine or bigger system. One basic form of machine guarding is called guarding by location According to OSHA this involves positioning or designing a machine so that the hazardous parts are away from areas where employees work or walk or alternatively installing enclosure walls or fences that restrict access to machines.

OSHA Quiz 8 Machine Guarding. Replace it at the end of the shi L. 2 Identifies emergencies that might reasonably occur and provides procedures for alerting people about an emergency.

Likewise what are the 2 types of primary safeguarding methods. When the operation of a machine or. It may stop the machine if a hand or any part of the body is inadvertently placed in the danger area.

The most common types of machine guards are. The safeguarding general rule to prevent hazards during servicing or maintenance of machines including all of the following except. A Pullback devices b Safety trip controls c Electro-mechanical sensing device d Two-hand control.

The point of operation the power transmission device and the operating controls. Types of Machine Safeguards Safeguarding machinery. There seem to be as many hazards created by moving.

_____ True or False. When you are protected by the with you opera ng the machine safeguards and others in the work 1. The focus of the course is on the hazardous motions and actions that contribute to different machine-related accidents and the safeguards used to help prevent those accidents.

Despite all machines having the same basic components their safeguarding needs widely differ due to varying physical characteristics and operator involvement. Primary machine can fill in as. 2 Fixed limited access guards.

Select the 4 answer options that apply. Machine guards sometimes referred to as safeguards are the protective devices that cover the hazardous or injurious parts of engineering machines. A wide variety of mechanical motions and actions may present hazards to the worker.

Guards are barriers which prevent access to danger areas. If a new guard causes interference 4. Types of Machine Guarding Restraint Devices.

The operator initiates the machine cycle. Primary methods Guards Devices Ensure employee protection. Probe detection and safety edge devices.

Which of the following explains how a guard protects workers. Primary Safeguarding Methods Two primary methods are used to safeguard machines. The following pages address the general requirements for machinery set forth by.

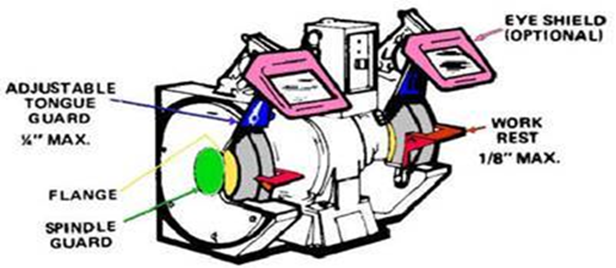

According to OSHA poor machine guarding leads to about 18000 amputations. These can include the movement of rotating members reciprocating arms and cutting teeth. Guard when periphery of blades is less than 7 above the floor or working level Guards with openings no larger than ½ Source of graphics.

Protective measures consisting of the use of specific technical means called safeguards guards protective-devices to protect workers from hazards that cannot be reasonably removed or sufficiently limited by design. 3 Identifies medical response options and designates an assembly area. Machine Guarding OSHA 10-Hour Outreach Training General Industry.

All machines consist of three fundamental areas. Prevent or detect operator contact with the point of operation or stop potentially hazardous machine motion if any part of an individuals body is within the hazardous portion of the machine. Moving machine parts have the potential to cause severe workplace injuries such as crushed fingers or hands amputations burns or blindness.

To ensure that employees are properly protected from machine hazards employers must assess the workplace and identify potential. Which of the following is a type of machine safeguarding. Machine guarding refers to protections on or around machines to safeguard human operators from hazardous conditions or injury.

There are four general types of guards and well discuss them in the next section. Commonly Used Machine Guards 12 Table 2. The CSA standard Z432 Safeguarding of machinery defines safeguarding as.

All machines consist of three fundamental areas the point of operation the power transmission device and the operating controls. This OSH Answers fact sheet is based. Safeguards are essential for protecting workers from these preventable injuries.

Lockout Tagout And Machine Guarding 2015 04 01 Ishn

What Is Machine Guarding And Why Is It Important Safetycompany Com

Machine Guarding Training Osha Standards Vubiz

Machine Guard Infographic The Point Of Operation Better Mro

Machine Guarding Creating Safe Work Environments For Humans And Machines

Machine Guarding Named To Osha S Top Ten Violations List For 2021 The National Provisioner

What Is Machine Safeguarding T P Supply Co

Machine Guarding Safetynow Ohs Training

Machine Guarding Approach Management Services

Machine Guard Safety Training From Safetyvideos Com Youtube

Crane Balancing Act Truck Cranes Crane Construction

Oshacademy Course 154 Machine Safeguarding Basic Module 2

Osha Standards For Industrial Companies Industrial Safety Health And Safety Poster Osha Safety Training

Poll Radial Arm Saws The Wood Whisperer Radial Arm Saw Saws Radial Saw

Machine Guard Safety Training Video Course Safetyinfo Com Youtube

Williams 12 X 3 4 Drive Impact Extension 6 113 In 2022 Schuylkill County Driving Valley View